ITS-60 Level Sensor for Fuel

- Solid-state heavy-duty design utilizing capacitive measurement technologies designed for fuel level applications

- Operating temperature range (-40°C to 85°C) (-40°F to 185°F) .

- Accurate level with tolerances of +/- 3% .

- Accurate level indication with any geometrically shaped tank.

- Designed to each customers unique specification.

- Output types: voltage, current loop, CAN-Bus J1939, PWM (CAN Open, resistor output end of first quarter 2022)

- Automatic self-calibrating sensor based on fuel type: diesel fuel, bio-diesel, eco-diesel.

- Sensor can be configured with either a minimum or maximum level switched output.

- Level indication and switch points can be configured with a delay (hysteresis) to prevent fluctuating output signals when there is movement inside the tank.

- Available in lengths from 200 mm (7.87”) up to 2300mm (90.55”).

- Designed and manufactured in Germany by BEDIA.

ITS-65 Level Sensor for hydraulic-and engine oils

- Solid-state heavy-duty design based on capacitive measurement principles designed for hydraulic and engine oil applications.

- Medium temperature range -50°C to + 150°C

- ITS-65 sensors can also be configured with an analog temperature output. Temperature is sensed from a sensor element located at the beginning of the circuit board.

- Accurate level with tolerances of +/- 3% .

- Accurate level indication with any geometric shape of the tank.

- Configured to each customer’s unique specification.

- Output types: Voltage, current loop, CAN-Bus J1939, PWM (CAN Open, resistor output end of first quarter 2022)

- Automatic self-calibrating sensor based on medium type or medium quality.

- Sensor can be configured with a minimum or maximum level switched output or with a temperature switched output.

- Level indication and switch points can be configured with a delay (hysteresis) to prevent fluctuating output signals when there is movement inside the tank.

- Available in lengths from 200mm (7.87”) up to 2300mm (90.55”).

- Designed and manufactured in Germany by BEDIA.

How ITS-65 is different from ITS-60?

- ITS65 is designed for hydraulic and engine oil level monitoring applications where the temperature of the medium could be up to 150°C.

- Increased operating temperature range (-40°C to 125°C).

- The ITS-65 has one level output and one optional output.

- Sensors configured with CANbus J1939 can indicate both the level and temperature parameters simultaneously and with

- customer software via a CANbus controller can indicate multiple level switch points, and temperature setpoints.

- ITS-65 with a temperature output includes a temperature element at the beginning of the circuit board.

Compatible CANbus Controllers

- The ITS series level sensors which are configured with a CANbus J1939 output can be easily interfaced with most CANbus based I/O controllers

- DFX Technologies offers a variety of CANbus controllers compatible with the ITS series sensors. These modules are designed for heavy-duty mobile applications utilizing solid-state technologies.

- The SS8 is DFX’s most powerful CANbus controller with 8x outputs, 3x analog/digital inputs, 2x serial communication ports for Modbus RTU RS-485 and CANbus J1939. This product is also embedded with IOT technology when remote monitoring and control are required.

- The SS8 can be provided with custom software specific to customer requirements.

ITS-Series Sensors

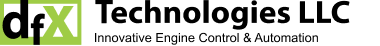

What is capacitive measurement principles?

ITS series sensors use capacitive level measurement technology to accurately maintain correct level indication regardless of the variation in permittivity of different media types. A capacitor is formed by an electrically conducting plate and an aluminum tube. Depending on the level, the remaining air volume between the measurement electrodes varies. The resulting capacitive change

is detected and processed by the microcontroller.

The ITS sensors are equipped with a proprietary sensor structure that automatically calibrates the medium type. This calibration occurs at levels as low as 50%. Having a sensor that is capable of auto-calibrating, based on medium type or medium quality is an important feature for industrial equipment.

Conventional capacitive sensors available on off-highway industrial market are usually designed to measure only one specific medium type. This inability to correctly measure different medium types could lead to inaccurate measurements of up to 50% due to aging or change of the fuel and oil types.

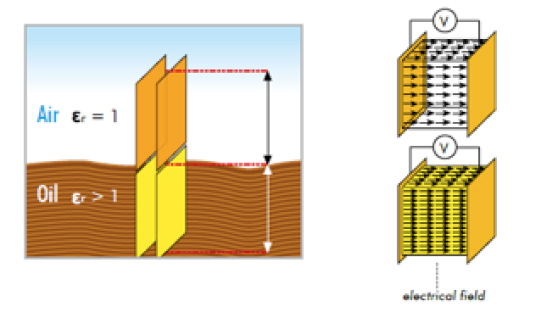

ITS Sensors – Tank geometry

- Irregular shaped tank geometry is becoming more common when OEMs are trying to utilize maximum space in their equipment designs.

- Having a non-linear tank design helps by increasing tank volume, however, it also makes measuring accurate tank levels an almost impossible task. Luckily, the ITS-60 and ITS-65 can be calibrated to adjust for the irregular tank designs.

- Calibration is accomplished by measuring 15 equally spaced reference points inside the tank from the bottom to the top of the tank. Volume is then calculated for each reference point. This data is then programmed into the sensor’s microprocessor during the manufacturing process. Each sensor then goes through extensive automated testing procedure to verify that parameters meet the customers specifications.

ITS Series Sensors Output Signal Types

- CAN: CANbus J1939

- Voltage (0-5V)

- Current (4 -20 mA)

- Resistance: 240-33 Ohm, 10- 180 Ohm, 0-90 Ohm, and custom Ohm ranges

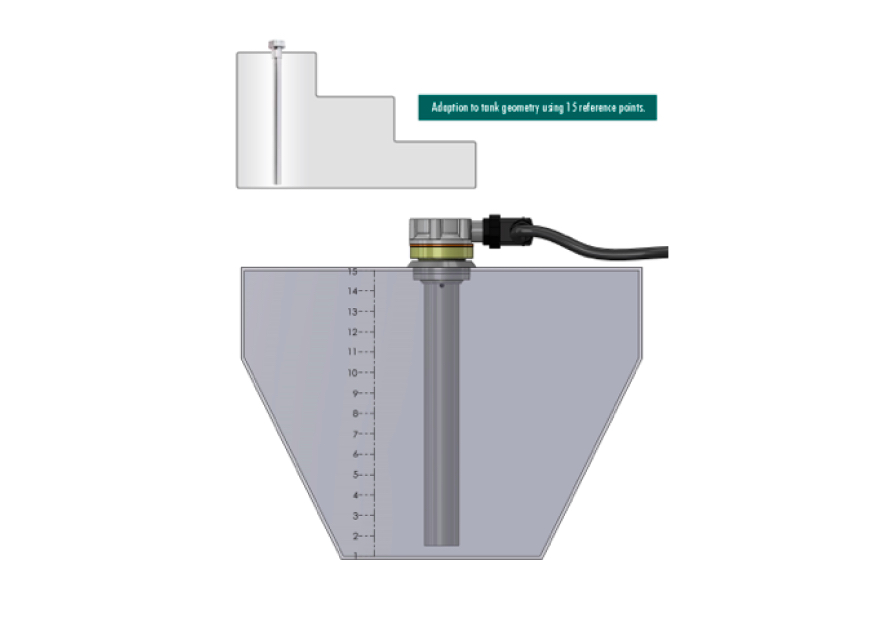

ITS Sensors –Switched Outputs

- For some applications having an accurate level indication is not enough. Each ITS sensor can also be configured with a switched output. Applications include low level alarm, high level shutoff or even the ability to shut down and engine prior to the engine running out of fuel.

- The ITS series sensors can be configured with either a low-side or high-side output signal.

- Switched outputs are short circuit protected and suitable for 500 mA.

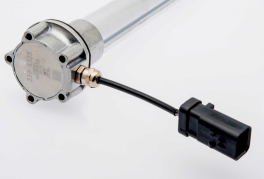

ITS Sensors – Available Connectors

- The ITS series sensors are available with a variety of connector options. Standard connectors for the US market include M12x1, solenoid valve connector or a Deutsch DT04-4P.

- The ITS-60 and ITS-65 can be also supplied with only flying lead cable to any length. This cable option gives our customers and our wire harness fabrication department the ability to add any customer required connector.

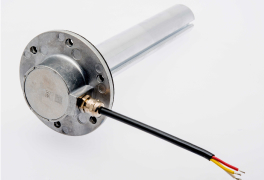

5-hole flange with connector DIN EN 175 301-803-A

5-hole flange with connector M12*1

5-hole flange cable with DEUTSCH DT04-4P

6-hole flange with Flying Lead Cable

ITS Sensors – Optional Connectors

Optional Cable with M12x1 Connector

Optional Cable with Overmolded Bayonet ISO 15170

Optional Cable with Super Seal Connector

Optional MIL-C-26482 Series 2

ITS Series Sensors Mounting Options

Available mounting options include:

- 5-Hole mounting flange

- 6-Hole mounting flange

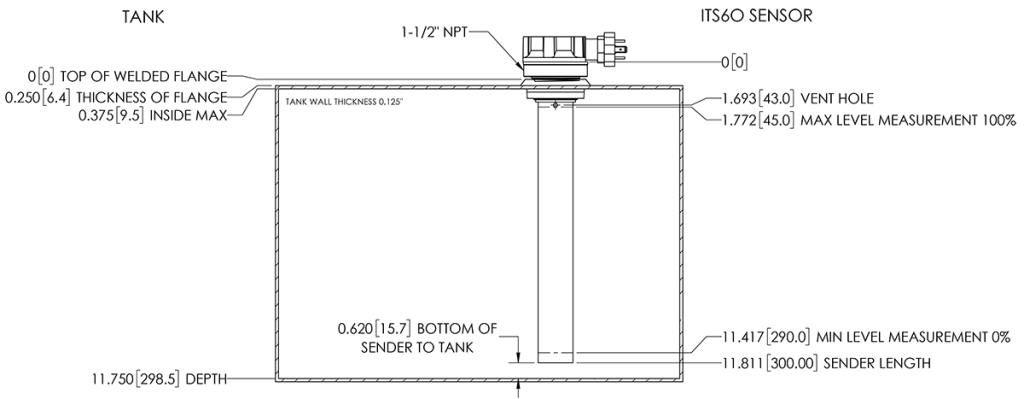

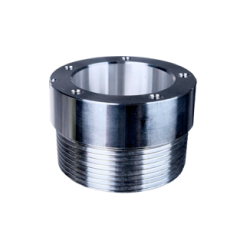

- 1-1/2” NPTF Adapter

- 2” NPTF Adapter

Example of the ITS Series Sensor with 1-1/2” NPT Adapter on a tank

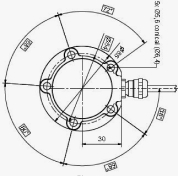

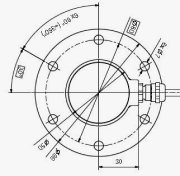

5-Hole ITS Mounting Flange

(Standard)

6-Hole ITS Mounting Flange

(Optional)

1-1/2” NPTF Adapter

2” NPTF Adapter

CLS Series Sensors – Markets & Applications

- Construction Equipment

- Marine

- Mobile Hydraulics

- Fuel and Hydraulic Tanks Mfg.

- Railroad

- Military

- Dewatering pumps

- Generators

- Fuel Level Remote Monitoring

- Road Manufacturing Equipment

- Mining

- Specialty vehicles

- Agriculture

- On-highway Truck and Bus

- Lift Trucks

- Woodchippers

- Light towers

- Concrete Pumps & Equipment

- Mobile Air Compressors