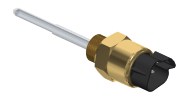

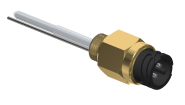

Shown with Deutsch DT Connector

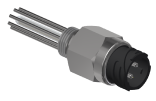

Shown with EMC Shielded Cable Option

- The CLS 40/45 series is designed for the industrial engine and construction market. Typical applications include engine oil and coolant levels, construction equipment, specialty vehicles, agriculture machinery, hydraulic system or any other oil-based or water-based level monitoring requirement.

- CLS series 40/45 are available in 2 different DC voltage ranges:

1. 9 – 36 VDC: CLS-40 Series

2. 4.5 – 18 VDC: CLS-45 Series - CLS sensors can be configured to detect either low-level or high-level applications, such as an overflow shutoff or automatic refilling systems.

- Each CLS-40/45 sensor has an E1-type approval with ECE regulations No.10, CE marking in accordance with directive 2014/30/EU and 2011/65/EU.

- IP Rating: Sensors are available in many connector & cable configurations. IP rating will vary based on the selected connector.

- Sensor operating temperature range: -40°C to 125°C (-40°F to 257°F)

- Medium temperature range:

1. water: -40°C to +125°C (-40°F to +257°F)

2. oil: -40°C to +150°C (-40°F to +302°F) - Custom stainless-steel options are also available for corrosive liquids such as for diesel exhaust fluid (DEF).

- Designed and manufactured in Germany by Bedia.

- CLS-40/45 Point level sensors are custom configured to each customers unique application.

- Sensors can be configured to function in water-based or oil-based mediums. Typical level monitoring applications include:

1. Water-Based Level Monitoring: Engine coolant, DEF, fresh water, wastewater, bilge water, water glycol mixtures.

2. Oil-Based Level Monitoring: Engine oils, hydraulic oils, diesel/biodiesel and brake fluids.

3. CLS series sensors can also be used to detect water in oil or water in fuel which is ideal for equipment requiring water separators. - The CLS’s compact solid-state design is perfect for high vibration applications. Unlike a typical float switches, the CLS series sensors are resistant to vibration.

- Point level monitoring advantages: Typical industrial engines use oil pressure and coolant temperature switches to detect critical low-level conditions, however these mechanical switches react slowly especially if there is no coolant in the radiator for the sensor to detect. CLS-40/45 sensor will react immediately once sensor detects a low-level condition. Being able to detect critical low-level conditions quickly on an industrial engine can help reduce costly downtime caused by engine failures.

- Output types: Low-side, high-side, analog output or as a proportional switched output.

- Custom sensors and connector configurations are available on special request.

CLS 40/45 Connector & Cable Options

| No Pins | Connector Options | IP Rating |

| 3-Pin | Deutsch DT (DFX Standard) | IP-67 |

| 4-Pin | Bayonet ISO 15170 | IP-69 |

| 4-Pin | Aptiv Metri-Pack Series 150 | IP-67 |

| 3-Pin | Bayonet 16 S | IP-67 |

| 3-Pin | Fine Thread M 27×1 | IP-67 |

| 3-Pin | Bayonet 10 SL VG 95234 | IP-67 |

| 3-Pin | Fine Thread 5/8-24 UNEF-2A VG 95342 | IP-67 |

| 3-Pin | DIN EN 175 301-803-A Solenoid Valve Type | IP-65 |

| Cable | Over-molded Cable Standard (Custom Lengths) | IP-69 |

| Cable | Over-molded Cable with EMC Shielded (Custom Length) | IP-68 |

Deutsch DT

Bayonet ISO 15170

Aptiv Metri-Pack

Bayonet 16 S

Fine Thread M27x1

Bayonet 10 SL VG 95234

Fine Thread 5/8-24 UNEF-2A VG 95342

DIN EN 175 301-803-A Solenoid Valve Type

Standard Cable

Cable with EMC Shielding

CLS 40/45 Sensors with cable can be customized to customer length and connector requirements

Shown with Bayonet 10 SL VG 95234 Connector

Shown with EMC Shielded Cable Option

- The CLS 20/25 series is designed for the Railroad and Railway Equipment markets which require certification approval to railway standard DIN EN 50155 or fire behavior according to DIN EN 45545-2.

- CLS series 20/25 are available in 2 different DC voltage ranges:

1. 9 – 36 VDC: CLS-20 Series

2. 4.5 – 18 VDC: CLS-25 Series - CLS sensors can be configured to detect either low-level or high-level applications, such as an overflow shutoff or automatic refilling systems.

- IP Rating: Sensors are available in many connector & cable configurations. IP rating will vary based on the connector selected.

- Sensor operating temperature range: -40°C to 125°C (-40°F to 257°F)

- Medium temperature range:

1. water: -40°C to +125°C (-40°F to +257°F)

2. oil: -40°C to +150°C (-40°F to +302°F) - Custom stainless-steel options are also available for corrosive liquids such as for diesel exhaust fluid (DEF).

- Designed and manufactured in Germany by Bedia.

- CLS-20/25 Point level sensors are custom configured to each customers unique application.

Sensors can be configured to function in water-based or oil-based mediums. Typical level monitoring applications include:

1. Water-Based Level Monitoring: Engine coolant, DEF, fresh water, wastewater, bilge water, water glycol mixtures.

2. Oil-Based Level Monitoring: Engine oils, hydraulic oils, diesel/biodiesel and brake fluids.

3. CLS series sensors can also be used to detect water in oil or water in fuel which is ideal for equipment requiring water separators. - The CLS’s compact solid-state design is perfect for high vibration applications. Unlike a typical float switches, the CLS series sensors are resistant to vibration.

- Point level monitoring advantages: Typical industrial engines use oil pressure and coolant temperature switches to detect critical low-level conditions, however these mechanical switches react slowly especially if there is no coolant in the radiator for the sensor to detect. CLS-20/25 sensor will react immediately once sensor detects a low-level condition. Being able to detect critical low-level conditions quickly on an industrial engine can help reduce costly downtime caused by engine failures.

- Output types: Low-side, high-side, analog output or as a proportional switched output.

Custom sensors and connector configurations are available on special request.

CLS 20/25 Connector & Cable Options

| No Pins | Connector Options | IP Rating |

| 3-Pin | Deutsch DT (DFX Standard) | IP-67 |

| 4-Pin | Bayonet ISO 15170 | IP-69 |

| 4-Pin | Aptiv Metri-Pack Series 150 | IP-67 |

| 3-Pin | Bayonet 16 S | IP-67 |

| 3-Pin | Fine Thread M 27×1 | IP-67 |

| 3-Pin | Bayonet 10 SL VG 95234 | IP-67 |

| 3-Pin | Fine Thread 5/8-24 UNEF-2A VG 95342 | IP-67 |

| 3-Pin | DIN EN 175 301-803-A Solenoid Valve Type | IP-65 |

| Cable | Over-molded Cable Standard (Custom Lengths) | IP-69 |

| Cable | Over-molded Cable with EMC Shielded (Custom Length) | IP-68 |

Deutsch DT

Bayonet ISO 15170

Aptiv Metri-Pack

Bayonet 16 S

Fine Thread M27x1

Bayonet 10 SL VG 95234

Fine Thread 5/8-24 UNEF-2A VG 95342

DIN EN 175 301-803-A Solenoid Valve Type

Standard Cable

Cable with EMC Shielding

CLS 20/25 Sensors with cable can be customized to customer length and connector requirements

Corrosion-Resistant Stainless Steel

Shown with Standard Cable Option

- The CLS 50/55 series is designed for the marine/maritime market requiring marine classification approvals: ABS, BV, CCS, DNV, KR, LR, NKK, RINA, RMRS. The CLS-50/55 is constructed from a corrosion-resistant stainless steel per standard X5CrNi 1810, EN 10088-3, 1.4301

- CLS series 50/55 are available in two different DC voltage ranges:

1. 9 – 36 VDC: CLS-50 Series

2. 4.5 – 18 VDCL: CLS-55 Series - CLS sensors can be configured to detect either low-level or high-level applications, such as an overflow shutoff or automatic refilling systems.

- IP Rating: Sensors are available in many connector & cable configurations. IP rating will vary based on the connector selected.

- Sensor operating temperature range: -40°C to 125°C (-40°F to 257°F)

- Medium temperature range:

1. water: -40°C to +125°C (-40°F to +257°F)

2. oil: -40°C to +150°C (-40°F to +302°F) - Designed and manufactured in Germany by Bedia.

- CLS-50/55 Point level sensors are custom configured to each customers unique application.

Sensors can be configured to function in water-based or oil-based mediums. Typical level monitoring applications include:

1. Water-Based Level Monitoring: Engine coolant, DEF, fresh water, wastewater, bilge water, water glycol mixtures.

2. Oil-Based Level Monitoring: Engine oils, hydraulic oils, diesel/biodiesel and brake fluids.

3. CLS series sensors can also be used to detect water in oil or water in fuel which is ideal for equipment requiring water separators.

- The CLS’s compact solid-state design is perfect for high vibration applications. Unlike a typical float switches, the CLS series sensors are resistant to vibration.

- Point level monitoring advantages: Typical industrial engines use oil pressure and coolant temperature switches to detect critical low-level conditions, however these mechanical switches react slowly especially if there is no coolant in the radiator for the sensor to detect. CLS-50/55 sensor will react immediately once sensor detects a low-level condition. Being able to detect critical low-level conditions quickly on an industrial engine can help reduce costly downtime caused by engine failures.

- Output types: Low-side, high-side, analog output or as a proportional switched output.

- Custom sensors and connector configurations are available on special request.

CLS 50/55 Connector & Cable Options

| No Pins | Connector Options | IP Rating |

| 4-Pin | Bayonet ISO 15170 | IP-69 |

| 3-Pin | Bayonet 10 SL VG 95234 | IP-67 |

| 3-Pin | Fine Thread 5/8-24 UNEF-2A VG 95342 | IP-67 |

| 3-Pin | DIN EN 175 301-803-A Solenoid Valve Type | IP-65 |

| Cable | Over-molded Cable Standard (Custom Lengths) | IP-69 |

| Cable | Over-molded Cable with EMC Shielded (Custom Length) | IP-68 |

Bayonet ISO 15170

Bayonet 10 SL VG 95234

Fine Thread 5/8-24 UNEF-2A VG 95342

DIN EN 175 301-803-A Solenoid Valve Type

Standard Cable

Cable with EMC Shielding

CLS 50/55 Sensors with cable can be customized to customer length and connector requirements

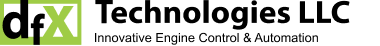

Understanding Minimum Level Detection CLS Point Level Switches Operating Current vs. Quiescent Current

Low-level monitoring programmed

with an Operating Current circuit:

An operating current configuration operates similar to a normally open circuit. When CLS sensor is in monitoring mode the output is OFF. When the sensor detects a low-level condition and after the programmed switching delay time the output switches from OFF to ON and stays ON until the level increases again above the minimum level or when battery power is removed from the sensor.

Low-level monitoring programmed

with a Quiescent Current circuit:

A quiescent current configuration operates similar to a normally closed circuit. When CLS sensor is in monitoring mode the output is ON. When sensor detects a low-level condition and after the programed switching delay time the output switches OFF and stays OFF until the level increases again above the minimum level. NOTE: Quiescent circuit is important when wire breakage indication is a requirement.

Switching delay, also known as hysteresis, is the time delay before the output activates. This time delay is available from 0 to 7 seconds. When a switching delay is configured it will help prevent false output activation, caused by movement in the medium. Custom switched time delays is available on request.

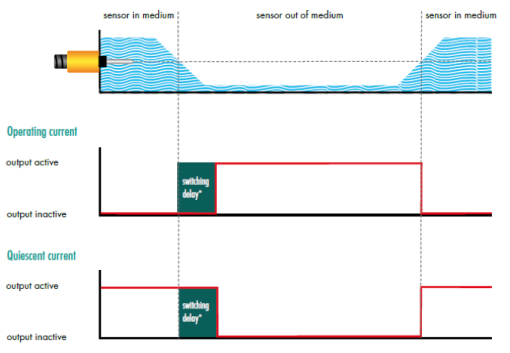

Understanding Maximum Level Detection CLS Point Level Switches Operating Current vs. Quiescent Current

Maximum level monitoring programmed

with an Operating Current circuit:

An operating current configuration operates similar to a normally open circuit. When CLS sensor is in monitoring mode the output is OFF. When the sensor detects a high-level condition and after the programmed switching delay time, the output switches from OFF to ON and stays ON until the level decreases again below the maximum level or when battery power is removed from the sensor.

Maximum level monitoring programmed

with a Quiescent Current circuit:

A quiescent current configuration operates similar to a normally closed circuit. When CLS sensor is in monitoring mode the output is ON. When sensor detects a high-level condition and after the set switching delay the output switches OFF and stay OFF until the level decreases again below the maximum level. NOTE: Quiescent circuit is important when wire breakage indication is a requirement.

Switching delay, also known as hysteresis, is the time delay before the output activates. This time delay is available from 0 to 7 seconds. When a switching delay is configured it will help prevent false output activation, caused by movement in the medium. Custom switched time delays is available on request.

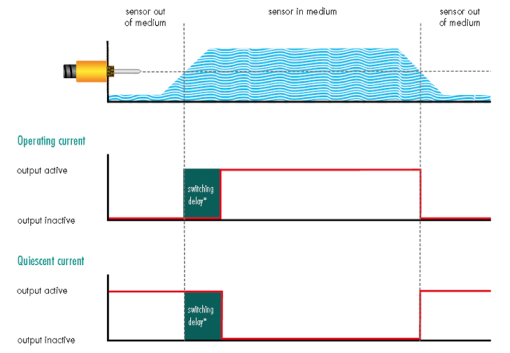

Mounting Position CLS Level Switches

A unique feature of the CLS sensor is that the sensor can be installed into a tank in any position, however in order to prevent false activations it’s recommended to install the sensor probe in an area inside the tank where the medium is dampened. If dampening is not available, then select a CLS sensor with a programed switched output delay. Switching delays can be configured with 0 or 7 seconds delay standard. Other delay times are available upon request.

There is note of caution when installing a CLS sensor designed for water-based liquids: If sensor is installed on top of a non-conductive tank, and if your probe is not immersed into the liquid then there is a possibility that the sensor may not function correctly. Errors could occur because the CLS sensors for water uses the water-based medium as a reference potential. In all other applications where the sensor probe makes contact with the medium the sensor will function correctly without issues.

For a water-based sensor to function correctly it is mandatory that the sensor probe has a minimum of 7 mm (0.275”) clearance from the sides of the access port.

CLS sensors can be installed into tanks, gearboxes, engine or transmission oil sumps, brake fluid containers and any other fluid container utilized on vehicles or equipment.

Contact one of our product specialists to determine the best sensor specification for your requirement.

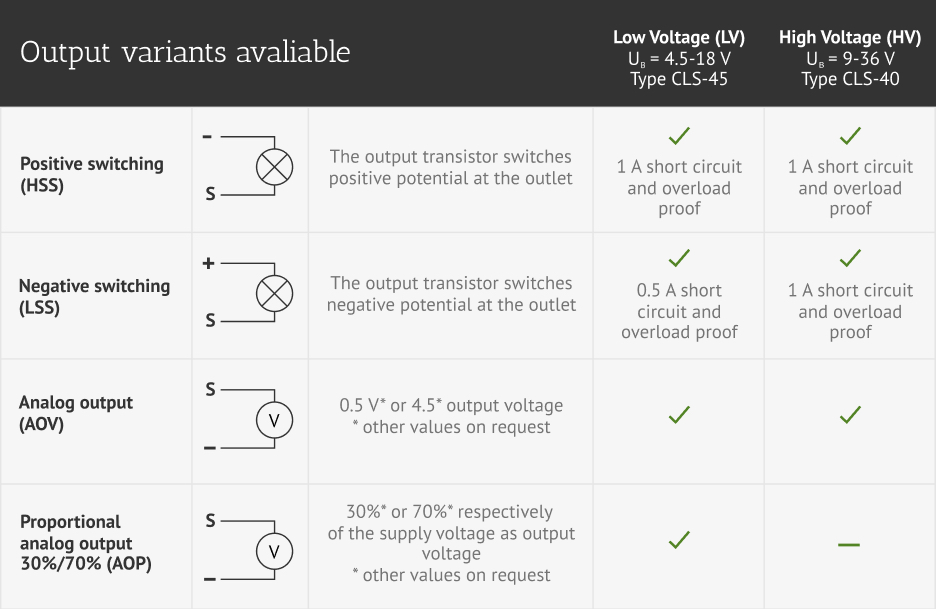

Output Types CLS Point Level Switches

CLS sensors are available in a variety of output types:

- Low-side negative switching (DFX Standard)

- High-side positive switching

- Analog output where the output is either 0.5 V or 4.5 V

(other values available on special request) - Proportional analog output where the output is either 30% or 70% respective of the supply voltage as the output voltage (other values available on special request).

Since CLS sensors are micro-processor-controlled, sensors can be configured with unique features such as fault indication delay (also known as hysteresis) and a self test feature, which verifies that the sensor is functional every time the sensor is powered on. These unique features together with the CLS’s solid-state technology makes these point level switches extremely reliable sensors.

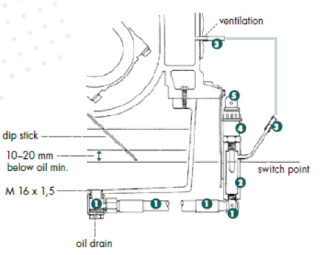

Accessories CLS Level Switches

DO YOU WANT TO MONITOR OIL LEVEL IN YOUR ENGINE OR TRANSMISSION OIL SUMP PAN?

Adding this simple accessory mounting bracket with air vent to your equipment enables the installation of a CLS point level sensor on the outside of the oil sump utilizing the oil drain as the oil access port.

This unique bracket design can be positioned to the correct switch point level and held securely in place with the heavy-duty mounting flange.

Accessories I/O Controllers

Do you need more capabilities from your CLS level monitoring requirement?

CLS point level switches are typically interfaced with the engine ECUs, mobile PLCs, or simple alarms and indicator lights. For applications requiring more capabilities a CLS point level sensors can be interfaced with an optional IO module.

DFX Technologies manufactures a variety of electronic IO controller modules. Utilizing a DFX I/O controller with our custom software can offer many capabilities such as:

- Converting the level output state to a CANbus J1939 serial message, so that faults related to the level can be viewed on the equipment’s HMI display

- Converting the level output state to Modbus RS-485 serial messages which is ideal for interfacing

with a PLC - I/O module can independently power up a CLS sensor and then check level prior to engine start (important for engine oil level)

- I/O module can shut down an engine when a CLS sensor detects a critical low-level or high-level condition

- Telemetry remote monitoring via email or text messages when a CLS detects a critical low-level

or high-level condition

Please contact DFX Technologies engineering for your custom control requirement.

AE-120S

SS-8

Custom Capabilities CLS Level Switches

CAN’T FIND A SENSOR FOR YOUR APPLICATION? WE WANT TO HEAR ABOUT YOUR REQUIREMENTS!

- Sensor body material and plating

- Extended probe lengths up to 80 mm (3.14”)

- Fault delay timing

- Sensor self-test timing

- Customer specific connector and cable types

- Operating voltage

- Thread Size

- Custom medium types

- Output signals

- Sealing O-ring material

- High-viscous oil application

- Custom plug-in-play wire harnesses

With sensing pin 80 mm long

For high-viscous oils

With integrated grounding pin for use in plastic containers

CLS Series Sensors – Markets & Applications

- Industrial

- Engine Oil Sump

- Overfill protection

- Railroad

- Transmission Oil Sump

- Biodiesel

- Marine/ Maritime

- Break Fluid Monitoring

- Machinery Lubrication

- Escalator

- Condensation Monitoring

- Chain Lubrication

- Mobile Hydraulics

- DEF Diesel Exhaust Fluid

- Factory Automation

- Diesel and Hydraulic Tanks

- Radiator Coolants

- Fresh Water Monitoring

- Water Separators

- Pump Coalescer Oil Level

- Wastewater Monitoring

- Gearbox Oils

- Automatic Refilling Systems